STO Heavy duty belt grinding and polishing

MODEL STO HEAVY GRINDING AND POLISHING FOR ROUND PRODUCTS

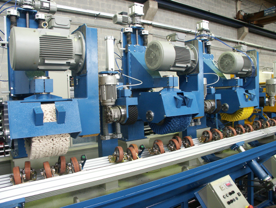

An heavy payload machine with high power installed which find best application in working on big dimensions and heavy products where are required working processes with higher pressure and stock removal.

STO finishing units, horizontally disposed, get in contact with the products from the top and a transport system made of roller conveyors opening on 120 degree, with more motorized single or double pinch rolls, installed before or after each unit.

The machine set up, simple and intuitive, keeps as reference the products centre, and is obtained by simply input of the diameter to be worked.

Special design that take care of many aspects of the working process, despite big dimensions of units and structure this machine is equipped with a very fine regulation of the working pressure and with gentle but quick in and out movement of the unit at the presence of the products to be worked.

Another aspect particularly improved is the STO system is the collection of the working muds and cleanness of the machine, important especially when high quantity of material are removed during working cycle, and to reduce maintenance time.

On demand it is possible to have a two way grinding directions system with step less inversion of the piece feeding.

HEAVY Grinding and Polishing of Round products, TUBES, PIPES and BARS

STO grinding unit detail

STO with 3 Units

STO 4 units

HANDLING AND ANCILLARY EQUIPMENT

STO is an automatic machine designed with modular system componible according to customer demand with the following parts and accessories.

-

a)BELT GRINDING units.

-

b)MIRROR POLISHING units.

-

c)COMPLETE HANDLING systems either for short and long products for example such as roller conveyors or transporting belts and dedicated loading and unloading devices.

-

d)Automatic loading and unloading tables or cradle.

-

e)PACKING MACHINE to close each single pipe into a plastic bag.

-

f)FILTRATION SYSTEM, sized on the machine dimensions and performances, filter of different type are added to treat either the coolant liquid , working mists and dusts generated during the production cycle.

-

g)SPECIAL DEVICES to be considered on a case by case basis will be possible to integrate in the machine measure devices for dimensions and roughness.

STO roller conveyor

STO wet working

STO polising units