MODEL:

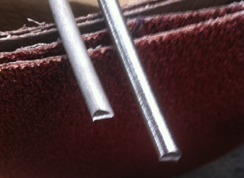

PLN Serie is based on orbital working concept, where one or two belts, acording to model, wrap the products to be worked. while these are feeded throguth the machine, while.

A constant and quality all round polishing is achieve thanks to the high speed of the system and controlled working pressure.

The system allow the work of round bars or tubes also in case of endless products and required limited resources in term of handling equipment and spaces.

PLN

Applications

The machie can work round products in general, for example seamless or welded tubes, bar or wire, in case of bar to bar, coil to coil or coil to bar systems.

The target results can be for example:

- Cosmetic finishing.

- Defects removal

- Roughness improvement

- Reduction of noise during NDT.

- Cleadning from oxide layer, rust or impurities

- Removal of spirals or machining marks

For model PLN

Carachteristics

Orbital

PLN machines are offered in different configuration and dimensions, according to application for example to work on small products with high feeding speed or to process big diameters with the scope of high stock removal.

The machine can be easilyt intergrate in a production mill where more funcions are operated, and can be upgraded with numerous accessories and optioanls manage or improve the performances, such as laser gauges to measure the stock removal or before a NDT test to reduce of the back ground noise.

Alternatives to PLN

PLN- Available with different capacity and dimensions

Tubes, pipes and bars, bundle to bundle, coil to coil, before cut to length

From 4 to 15 mm - 5 - 114 mm - From 60 to 350 mm (Other on demand)

Length from 2,5 mt up to endless (according to transport system)

Grinding belts with different length and width according to model

Dry with dust collector .

Belt Grinding

PLN Technical

MODEL

Workable products

Workable dimensioms

Diameters

Length

Tools used

Working conditions

SURFACE ENGINEERING s.r.l.

Street: Via Quadretto 5 - 9

Post code: 20013 City: Magenta

State: ITALY - EU

Ph: +390297003431

Fx: +390297296473

@: info@surfaceenginering.it